Rock wool sandwich panel is a kind of sandwich panel made of rock wool as raw material. Rock wool sandwich panel gives full play to the unique properties of rock wool core material, in fire prevention, thermal insulation, sound absorption and sound insulation, etc. has a significant effect.

The disadvantage of rock wool sandwich panel is that it is not strong enough, but it is suitable for steel structure workshop, simple activity room roof, wall, air clean room ceiling and partition and other places.

Color steel rock wool sandwich panel and its production process to achieve in the factory through automated equipment will be rock wool and steel plate composite into a whole, thus changing the previous rock wool panels need to be on-site composite way, in order to meet the requirements of the building thermal insulation, acoustic insulation, fire prevention and other requirements of the premise, but also to achieve the ******, high efficiency, ******, safety goals. The product has been widely used in Europe, has been mature and perfect.

Advantages

Rock wool sandwich panel gives full play to the unique properties of rock wool core material, fire prevention, thermal insulation, sound absorption and sound insulation, etc. has a significant effect.

1, fire performance ******: rock wool sandwich panel using raw materials, production processes and formulations, so that it has a very good fire performance. Tests show that it has more than 1000 ° C fire resistance. The rock wool sandwich panel has passed the test of Italian ****** testing agency GLOROANO S.P.A. According to the standards of International Organization for Standardization (ISO), British BS and German DIN, the rock wool sandwich panel meets the requirements of fire prevention standard M.I14/09/61 letter No.91 and D.M.30/11/83. Test results are as follows: 1) 50mm thick rock wool sandwich panel RE130 80mm thick rock wool sandwich panel REL60 100mm thick rock wool sandwich panel REL 120

(2) good thermal insulation: rock wool sandwich panel thermal insulation performance is based on the thermal conductivity of rock wool = 0.043W / ㎡ K, calculated on the basis of the thickness of the corresponding proportion of rock wool core material.

3) Acoustic and thermal insulation ************

Acoustic insulation: rock wool sandwich panel has a significant attenuation effect on noise transmission, especially suitable for places where there are designated flights passing through. In addition, after the use of rock wool roofing panels, rain, hail on the building’s roofing steel plate impact caused by indoor sound, but also significantly weakened. Through testing, in accordance with ISO 717/82 and UNI 8270/7 standards, the selection of density of 120kg/m³ rock wool as the core material of the sandwich panel, the sound insulation effect can be achieved RW = 29-30 dB

Sound absorption: rock wool sandwich panel also has excellent attraction effect, it can absorb a wide range of frequency range of sound. According to ISO 35/85, the sound absorption performance level of rock wool sandwich panels reaches DELTA LA=15.7dB(A).

Characteristics

1, good stiffness: due to the rock wool core material and two layers of steel plate bonded into a whole, working together, in addition to the roof plate on the surface of the wave pressure type, its overall steel is far better than the pressure plate clamped rock wool (glass wool) on-site composite panels. The sandwich panel is fixed with purlin through connectors, which greatly improves the overall steeliness of the roof and strengthens the overall working performance of the roof. Selection of rock wool sandwich panel, can be used for larger purlin distance, so it can save purlin dosage 1/3~2/3.

2、Reasonable buckling method: rock wool roofing board adopts buckling connection method, which avoids the hidden trouble of water leakage of roofing board seams and saves the amount of accessories.

3、Reasonable fixing method: Rock wool roofing panel adopts special M6 self-tapping screws to fix with purlin, which can effectively resist the external force such as typhoon. The self-tapping screws are set in the crest position on the upper surface of the roof panel, and special waterproof construction is adopted to avoid waterproof weak point.

4, short installation cycle: rock wool sandwich panel, because the scene without secondary processing, not only can keep the surrounding environment clean, does not affect the normal conduct of other processes, and can greatly shorten the installation cycle of the plate, rock wool sandwich panel daily average installation area of 600 ~ 800 square meters.

5, anti-scratch protection: rock wool sandwich panel production, can be pasted on the surface of the polyethylene self-adhesive protective film, in order to avoid the transportation and installation process of the steel plate surface coating is scratched or abraded.

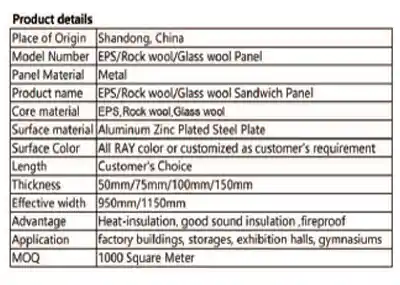

Product parameters

Thickness of upper/lower steel plate

0.4~0.8mm color steel plate/electrical and hot galvanized plate/stainless steel plate

Core material

(Mining) Rock wool capacity 120~150kg/m Thickness: 50-150mm

Side sealing steel strip or no side sealing steel strip

: 0.4mm~0.8mm galvanized plate

Effective width

950mm, 1150mm; thickness: 40mm-150mm; length: unlimited

Board surface protection form

Covered with PVC protective film

Applicable fields

Widely used in steel structure workshop, simple activity room roof, wall, air clean room ceiling and partition. Rock wool sandwich panel, generally can be customized according to customer requirements rock wool sandwich panel is a series of sandwich panels in the fire-resistant performance is superior.