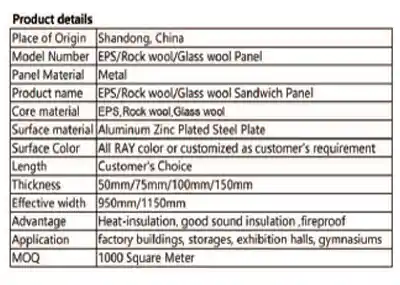

Material Characteristics

Broadcasting

Editor

(1) Glass wool sandwich panel with high closed cell rate and excellent energy saving effect;.

(2)Green environmental protection, no formaldehyde; and

(3)One time investment, continuous saving; (4)Unique glass wool sandwich panel, no formaldehyde.

(4) Unique insertion interface design, stronger anti-negative wind pressure ability.

(5)Diversified modeling, beautiful and elegant advantages: no cold bridge, rigidity, good flatness, glass wool A-class non-combustible; (6)Plug interface design, non-formaldehyde

(6)Tight insertion interface, no steel plate heat conduction

(7)Polyurethane side seal on both sides, blocking the core material water absorption pathway, prolonging the service life;; and

(8)Unique design of connection port, stronger anti-negative wind pressure ability; (9)Good performance of the core material.

(9) Good fire performance: suitable for large public buildings, industrial plants and other fire requirements of the building on the wall and roof.

Glass wool is to adapt to the needs of large-area laying and made of maki material, in addition to maintaining the unique thermal insulation, heat insulation characteristics, but also has a very excellent fire prevention, shock absorption, acoustic properties, is conducive to reducing noise pollution, improve the working environment is mainly used for: roof thermal insulation, roof thermal insulation, heat insulation of the wall of the steel structure of the plant, indoor thermal insulation, acoustic absorption, aquaculture roof roof thermal insulation and fire protection) heat preservation, insulation, fire prevention, acoustic, and the effect is very ideal. Fire prevention, sound absorption, the effect is very ideal. In construction, it can also be arbitrarily cut according to the need to have a better moisture-proof effect. It is an excellent thermal insulation, heat insulation, fireproofing and sound-absorbing material for workshops, roofs, walls and flat roofs.

Main sheet

broadcast

Edit

Plates

1. Surface/base plate (color coated plate, galvanized plate, stainless steel plate, aluminum foil, PVC, plywood, etc.)

1.1 Introduction to the performance of various plates (1) Color coated plate

The base plate is hot-dip galvanized or aluminum zinc-plated plate, and there is also an electro-galvanized base plate, and the surface paint does not fall off after bending;

For composite plate with color steel plate is generally two coated one baking (two coated one), and two coated two baking (two coated two) or there are quality problems such as serious loose edges, the middle of the loose heart, leakage of paint, large jagged edges, serious ellipse, jagged and so on can not be used for the production of composite panels.

(2) galvanized sheet

The bonding effect is not good sometimes not very good to deal with, need to be dealt with.

(3) Stainless steel plate

Good corrosion resistance, toughness and difficult to process; bonding effect is sometimes not very good, need to be dealt with.

(4) Aluminum foil

Reinforced aluminum foil is a kind of composite material with glass fiber reinforcement sandwiched between aluminum foil and kraft paper, with fire retardant, fire prevention and other functional characteristics, but also beautiful, durable, is a new generation of heat preservation, heat insulation, sound insulation, the ideal supporting thermal insulation layer.

(5) PVC

The main raw material of PVC foam board is polyvinyl chloride (PVC), which is characterized by smooth and beautiful surface, light weight, flame retardant, moisture-proof, sound insulation, corrosion prevention, easy to cut, good weather resistance, acid and alkali resistance and easy to clean.

(6) Plywood

Due to the limited length of each plywood, the compact effect is not very good, and the crack phenomenon is difficult to solve.

Main core materials

2. Core material (mainly: EPS, rock wool, glass wool, flame retardant paper honeycomb board, polyurethane, etc.)

2.1 Introduction to the performance of various core materials (1) Foam Board

By the disposable polystyrene (EPS) particles as raw materials, the shape of fertilizer particles, heated pre-foam, into a white pearl-like larger particles, and then in the mold heating and pressing molding made of foam plastic panels with a micro-fine closed-cell structure.

(2) Polyurethane High energy-saving performance

Fire insulation performance is excellent material for making composite panels of polyurethane weight is generally 30 kg -40 kg.

(2) Rock wool boards

Basalt is the main raw material, after high temperature melting, made of inorganic fibers by high-speed centrifugal equipment, while uniformly adding a certain percentage of the

Adhesive baked into a large board, according to the production needs of cutting into rock wool strips, rock wool is non-combustible body, fire performance is good.

(4) glass wool

Is a lightweight, heat-resistant, rich in elasticity, or else thermal insulation materials, widely used in chemical, pharmaceutical, factories, heavy industry machinery and equipment, construction, cars and ships, aerospace, is an ideal heat-breaking, fire prevention, sound-absorbing materials.

(5) Flame retardant paper honeycomb panel

It is a national B1 grade fireproof material with the advantages of good flame retardancy, good compressive strength, only carbonization and no combustion, no toxic substances, and the waste can be completely recycled and reused, etc. It is an ideal substitute for the core material of polystyrene, polyurethane and rock wool.

(6) Polyurethane

It is a material with excellent fireproof and heat preservation performance, and the capacity of polyurethane board used for composite board is generally 30-40 kilograms.